Serving the Well Service Industry

As lubrication system specialists, we know the critical importance of specifying, designing, and installing lubrication systems that fit the applications’ demands.

That’s why we keep a variety of quality parts stocked for immediate delivery, including SKF Lincoln, Alemite, Lubrication Scientifics, and more.

Our ability to specify the correct packing lube system for frac pumps can alleviate environmental issues, improve up-time, efficiency, and performance, cut costs on lubricant spending, and make it easier for mechanics to perform pump maintenance.

One such instance was a project for a pressure pumping company running 10 fleets of frac pumps in the Eagle Ford.

The Challenge

Our client was experiencing field performance issues throughout their frac fleet with their packing lubrication system. Specifically, the previous system was designed to discontinue flow of lubricant to the fluid end upon failure of one packing point.

As the fracking industry evolved and the hours of operation increased, the maintenance time of the systems also increased proportionately.

Furthermore, the customer struggled with frequent refilling of their small reservoir. This limitation created risk of introducing contamination into the reservoirs and concern of safety hazards with operators in the Red Zone. The goal was to improve system reliability and design that would enhance packing life and up-time performance, while reducing the number of human touches.

The Solution

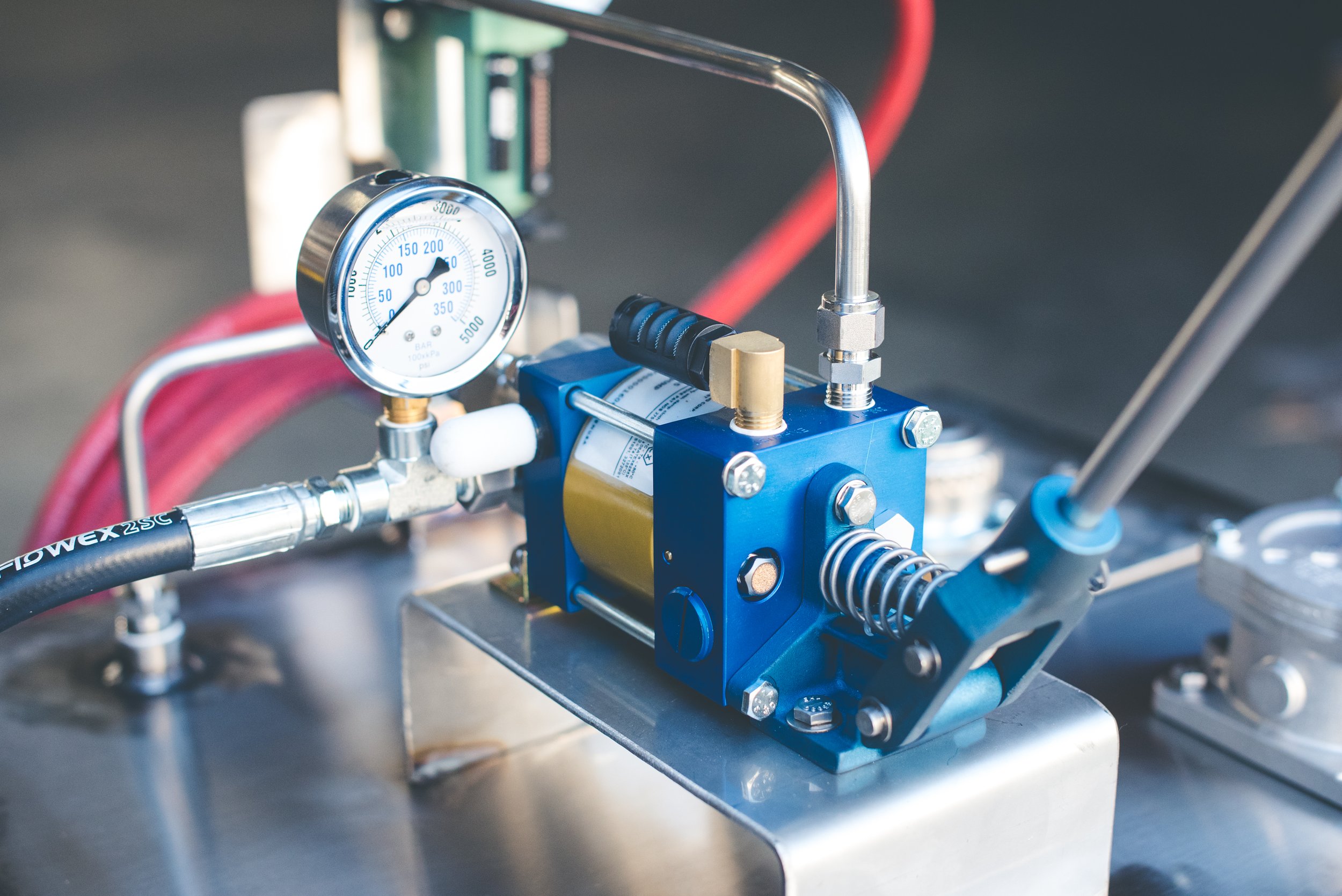

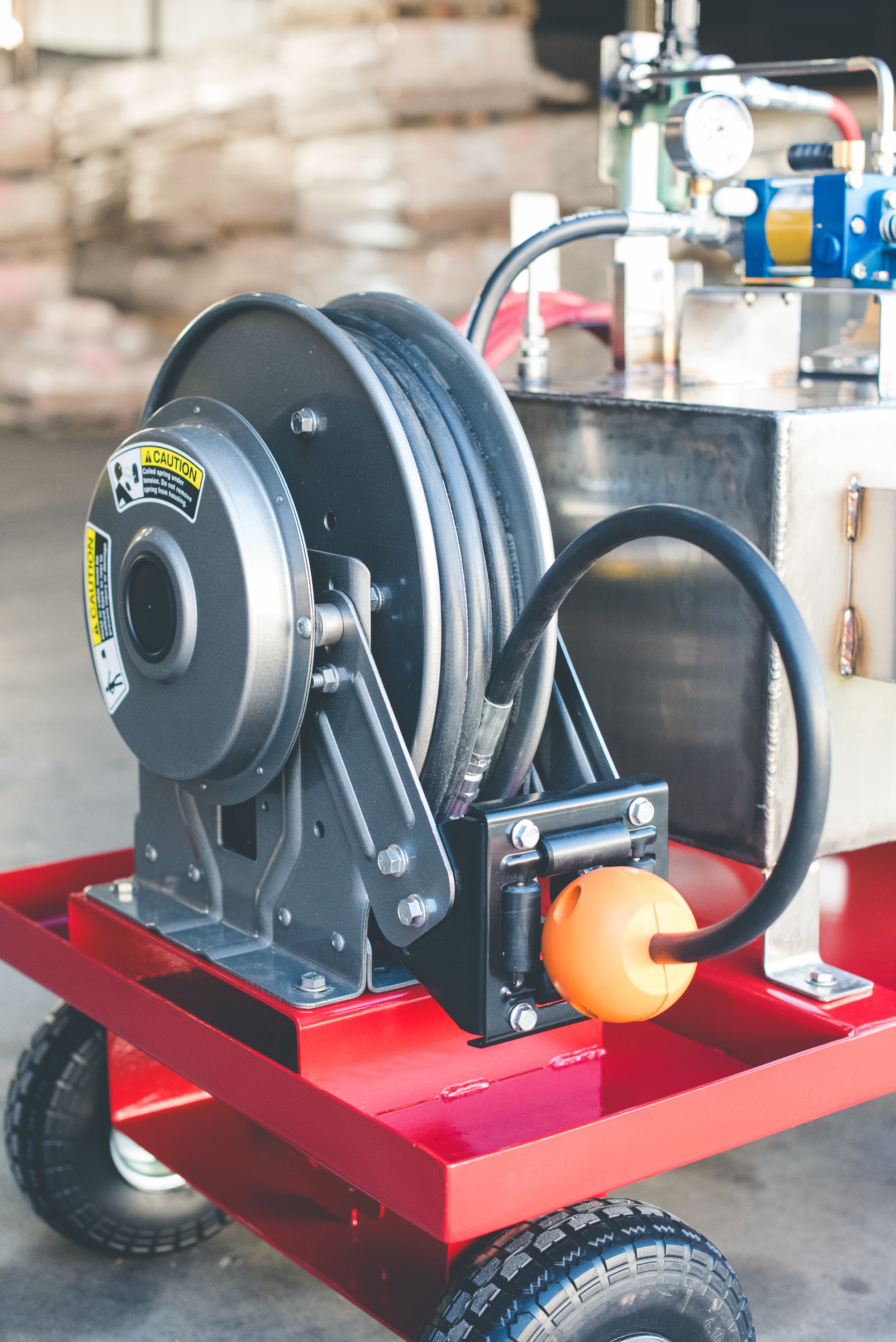

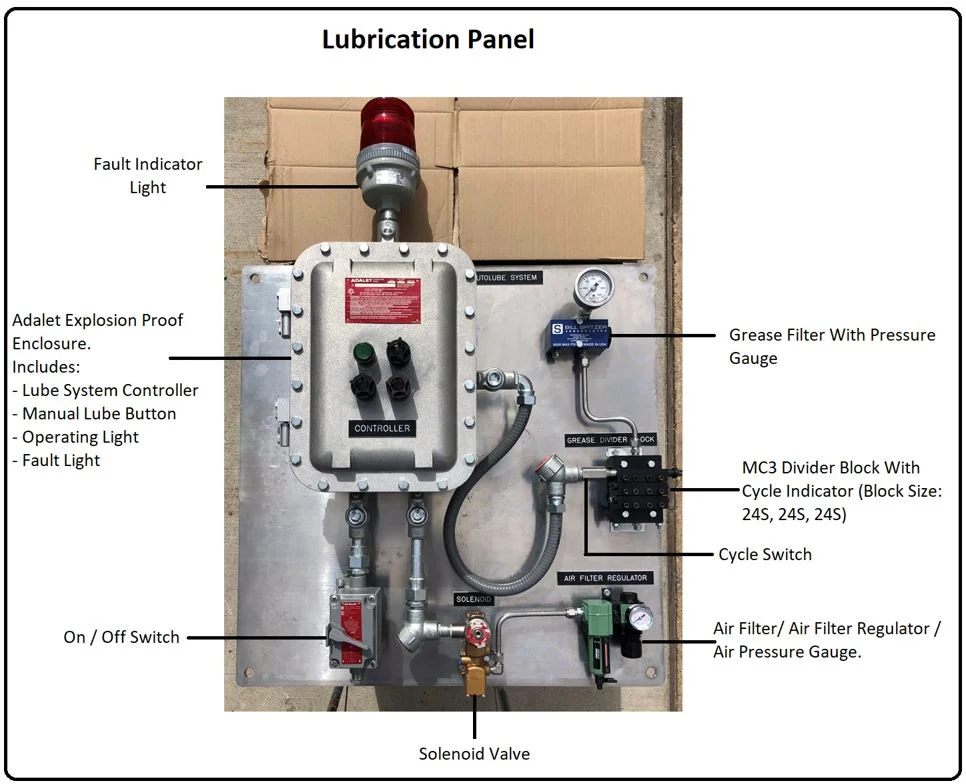

We advocated for a large (60-lb. capacity) single line parallel system with exceptional performance in harsh environments. The system included a filtration system on the reservoir lubricant fill port to combat contamination. Lube rates were engineered for increased efficiency by delivering smaller, precise shots of lubricant, more frequently.

We commenced a 365-day field test of our Spitzer FlowMaster II Packing Lube System for this client. We had four systems pumping from the “dirty” side of the manifold serving in numerous Zipper Frac’s throughout the year.

Key Outcomes

Increased average packing life from 50 to 130 stages

Expanded the reservoir capacity of the system by 87%

Decreased the frequency in refill of the reservoir from once every shift to every five days

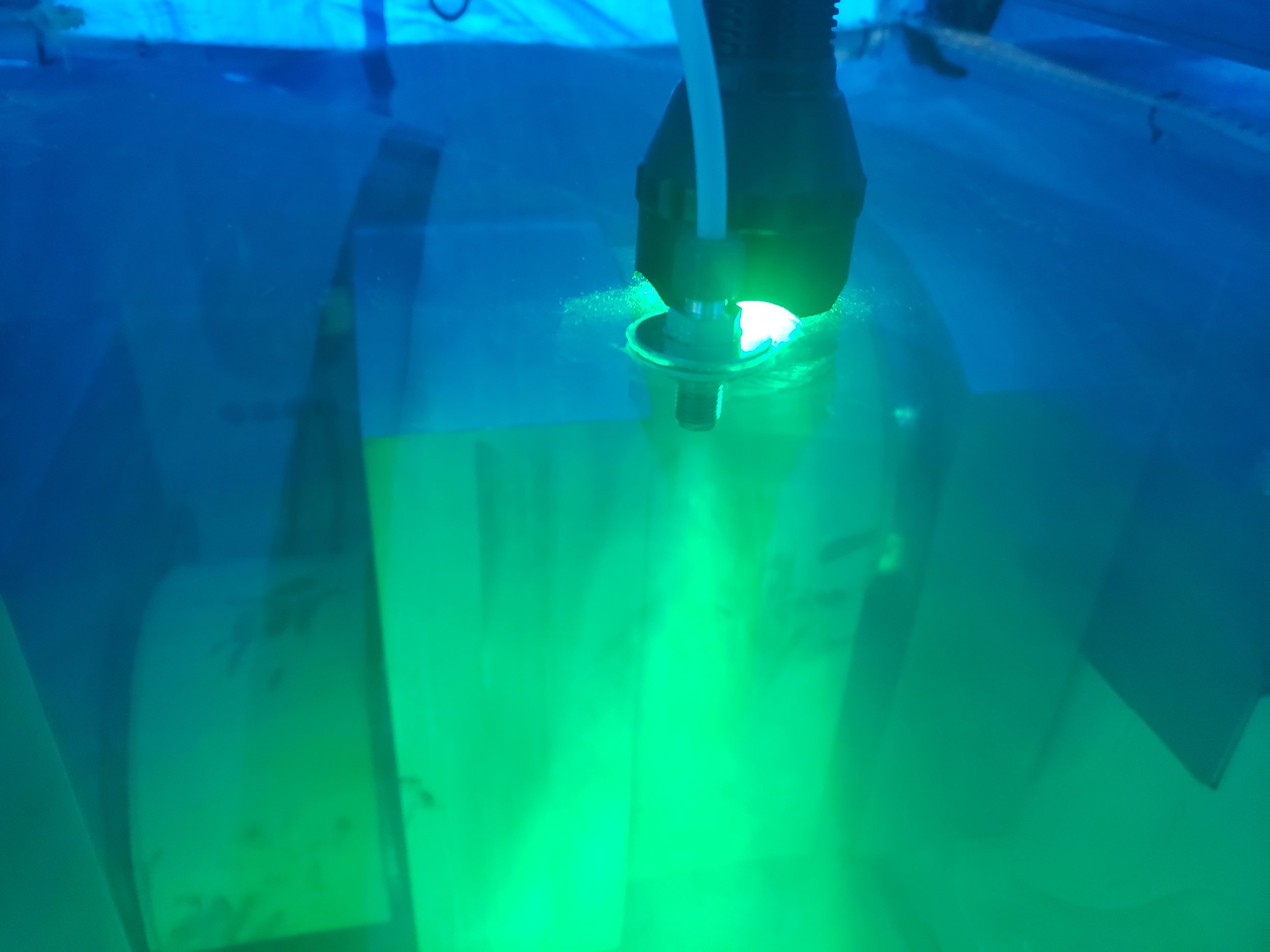

Mitigated contamination through filtration, resulting in zero component failures over the year

Achieved the return on investment in less than one year, based solely on packing life

Field and Engineering Support Services

Beyond providing automated lubrication systems we also provide field and engineering support services.

At BSA, we believe in a comprehensive approach to customer service. Many companies will be happy to sell you a product. They will take your order, ship it to you, and say thanks for the business. We can certainly do that for you. But we always look to do more.

We’re primed to support every stage of your frac pump’s lifespan, including:

Problem diagnosis and recommendations

System design to fit your exact needs at the right price

Reliable inventory and rapid response times

Installation services via highly qualified and experienced technicians

Supervision and commissioning to ensure flawless operation of our systems

Repairs and preventative maintenance as needed

Support and unmatched customer service

We also provide lubricant consumption analysis to determine current use and see where we can improve consumption rates. This includes assisting in the transition of a packing grease to a packing oil.

We’re Committed to Our Frac Market Customers

Why are we the right choice for your frac market needs?

Our variety of solutions and services promises the highest quality products, unmatched customer service, and comprehensive maintenance of your pumps.

This includes:

Qualified and experienced field technicians that will get your lubrication system repaired or replaced following best practice installation standards

Fabrication capabilities

Custom control packages designed to bring innovative technology to our lubrication system offering

High-quality lubricants available for frac pump fluid ends

If you’re in the frac market, we have the right solution for whatever need arises. Contact our team by calling 713-937-8977.

For a downloadable copy of this post, click here.