OIL MIST LUBRICATION SYSTEMS

Check out our most recent case study for more detail on an oil mist application

Check out our recent blog post about the benefits of oil mist for preservation on process equipment

Overview

Oil mist lubrication began in the United States around the early 1900s. Initially, it was used in machine tool and steel industries and quickly made its way into the refining, petrochemical, and paper markets. Oil mist is a straightforward process made by combining instrument air, or nitrogen, with oil through a venturi nozzle. The system will generate mist while these three components are present and operating properly. A properly designed oil mist system will reduce oil consumption and minimize heat from fluid friction, when no oil sump is maintained in dry mist applications. Continuous oil mist lubrication at low lube rates, matching actual bearing requirements, extends bearing life – while the slight positive pressure on the bearing housing prevents moisture intrusion. This holds true for operating equipment as well as for idle, or back-up equipment. Oil mist makes for a great method of preservation for equipment being stored (long-term or short-term).

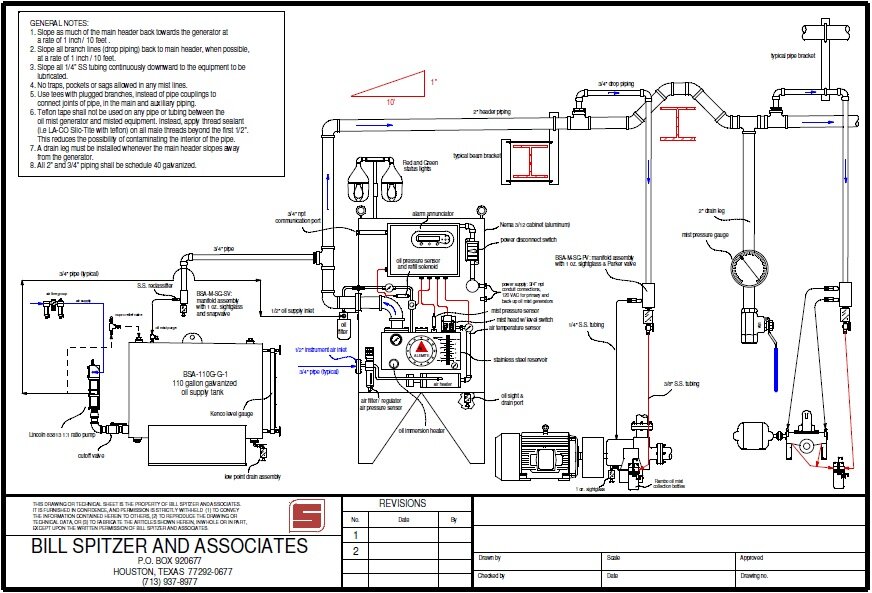

Bill Spitzer & Associates (BSA) can create customized solutions to fit the needs, obstacles, or specifications for the entire oil mist system. The customized approach enables BSA to provide a turnkey solution for design, installation, commissioning, operation, training, and preventative maintenance (PM) program implementation.

Key Components

Customizable & 6 Standard Sizes

NEMA 4x SS Enclosure

Filter/Regulator with Pressure Gauge

5-gallon SS Oil Reservoir

Oil Level Sight-Glass

Oil Heater & Thermostat

Oil Temperature Gauge

Oil Level Float Switch

Automatic Oil Refill Capability

Hi-Lo Mist Pressure Switch

Mist Pressure Gauge

Mist Pressure Alarm

LED Status Alarm Lights

LED System Parameter Indicator Lights

Air Heater

Backup Mist Generator

Bulk Oil Storage Tank

SS Oil Collection Containers

Pure & Purge Mist Kits

Rambo Oil Mist Collection Pot

SS Auto Drain Leg

Value

Within 24-hours or less, we react to customer needs and service for all types oil mist components and these lubrication related products: Lincoln, SKF, Alemite, Orsco, Patton, Perma, Kluber, and Lubrication Scientifics.

We approach all service calls with a sense of urgency and the understanding of equipment uptime, utilizing quality components helps BSA performance become repeatable and provides longer service life for your equipment.

Bill Spitzer & Associates PM programs ensure your oil mist system(s) continue to operate as designed and our experienced Service Technicians offer the industry a professional and competitively priced solution, even in an unplanned downtime.

Installed oil mist systems by BSA will reduce oil consumption, minimize heat from fluid friction, extend bearing life, prevent moisture intrusion, extend mean time between failure (MTBF), and safeguard stored equipment for short-term and long-term situations.

Examples

Centrifugal pumps

Electric motors

Steam turbines

Gearboxes

Blowers

Mixers

Gears, cams, spindles, slides and ways

Preservation of in-place turbomachinery that has been decommissioned

Preservation, both indoors and outdoors, for stored equipment:

Compressors, pumps, motors, gearboxes, turbines, mixers – generally any cavity that needs preserving

Markets

Petrochemical

Refining

Power Generation

Pulp and Paper

Machine Tool